Why Going Digital with BIM is a Game Changer for Manufacturers

The construction industry is no longer driven only by physical products and traditional workflows. It is now shaped by digital information, connected systems, and data-driven decisions. For building product manufacturers, this shift presents both a challenge and a powerful opportunity. At the center of this transformation is Building Information Modeling (BIM), which has moved beyond being a design tool to becoming a critical business enabler.

Manufacturers who embrace BIM are no longer limited to supplying physical products alone. They become digital contributors to projects, influencing design decisions, improving coordination, and strengthening long-term relationships with consultants, contractors, and owners. This change is redefining how manufacturers compete, collaborate, and grow in the modern construction ecosystem.

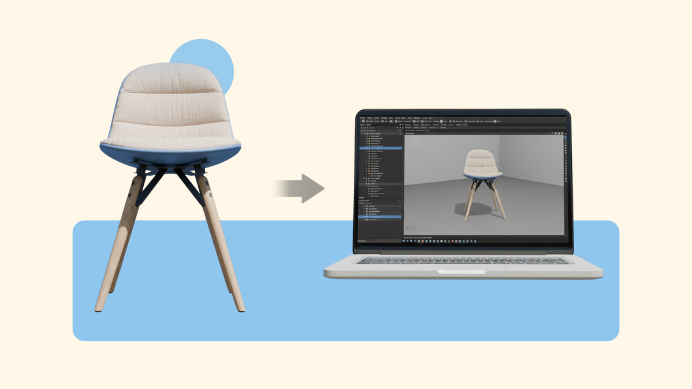

The Shift from Physical Products to Digital Assets

Traditionally, manufacturers delivered their value through catalogues, datasheets, and on-site coordination. Today, designers and engineers expect instant access to accurate digital product information inside their design environments. BIM allows manufacturers to convert their products into intelligent digital objects that carry geometry, technical properties, performance data, and compliance information.

These digital product representations allow specifiers to evaluate products earlier in the design process. As a result, manufacturers gain visibility long before procurement begins, increasing the likelihood of specification and reducing late-stage substitutions.

Stronger Market Reach and Brand Visibility

When manufacturers provide BIM-ready product models, their products become discoverable across global projects. Design consultants working in different regions can directly access and specify products without needing manual coordination. This creates a digital channel for visibility that goes far beyond traditional regional sales networks.

BIM content libraries, digital asset platforms, and open data environments enable manufacturers to position their products exactly where project decisions are made. This visibility translates directly into stronger brand recall and higher chances of repeat specification.

Faster Project Approvals and Reduced Design Risk

One of the biggest pain points in construction projects is late-stage design changes caused by missing or unclear product information. BIM-ready product data reduces this risk by allowing accurate coordination between architectural, structural, and MEP systems from the beginning.

Manufacturers benefit from fewer redesign requests, fewer RFIs, and fewer site-level conflicts. Products that are digitally verified during design move more smoothly through approval cycles, fabrication planning, and installation.

Improved Coordination with Construction Teams

BIM enables manufacturers to move closer to construction workflows. Installation details, tolerances, access requirements, and sequencing can be reviewed digitally before reaching the site. This reduces errors during execution and supports smoother collaboration with contractors and installers.

Prefabrication and modular construction further amplify this benefit. When products are digitally coordinated, they can be manufactured with higher accuracy, reducing waste, rework, and on-site adjustments.

Data-Driven Product Development

BIM also creates a feedback loop for manufacturers. Once products are embedded into digital projects and later connected to operations data, manufacturers gain insight into how their products perform in real conditions. This supports better design refinement, improved durability, and more responsive innovation cycles.

Instead of relying only on market feedback or warranty claims, manufacturers can now use performance data to guide future product development.

Sustainability and Regulatory Alignment

Sustainability is now a core expectation, not an optional feature. BIM allows manufacturers to embed environmental data such as embodied carbon, energy performance, recyclability, and material composition directly into their product models. This supports green building certifications, regulatory approvals, and environmentally responsible decision-making.

Manufacturers who provide transparent sustainability data through BIM are better positioned to meet global compliance standards and future climate regulations.

A Competitive Advantage That Cannot Be Ignored

The reality is simple. Manufacturers who do not go digital risk becoming invisible to the next generation of designers and project teams. Those who invest in BIM gain strategic advantages in specification, coordination, approvals, sustainability, and lifecycle performance.

BIM is no longer only about design efficiency. It is about business growth, digital presence, and long-term competitiveness in a rapidly evolving construction industry.

Closing Thoughts

Going digital with BIM is not just a technical upgrade for manufacturers. It is a fundamental shift in how products are presented, selected, coordinated, and operated throughout a building’s life. Manufacturers who embrace this shift move from being product suppliers to becoming digital partners in the construction ecosystem. Those who delay risk being left behind in a market that is rapidly moving toward fully digital project delivery.

Yatzar Asset is built to support manufacturers through every stage of their digital transition. From digital product creation to global project visibility, we enable brands to become part of modern construction workflows. The future of product discovery is digital.

Connect with us to explore how we can support your brand.